Lightweight polymers

Expancel® Microspheres for thermoplastics

Lightweight polymers

Expancel® Microspheres for thermoplastics

Expancel® Microspheres: A Superior Blowing Agent for Stable, Controlled Foaming in Thermoplastic Processing

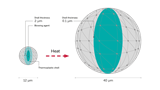

Expancel®microspheres feature a uniform, closed-cell structure that ensures a stable and controlled foaming process in thermoplastic applications. They serve as a phenomenal blowing agent, either on their own or in combination with chemical blowing agents, delivering consistent performance across a wide range of materials.

Expancel® microspheres are suitable for process temperatures up to 235°C (455°F) and are commonly used in PVC, TPR, TPU, and rubber. These microspheres offer significant advantages in thermoplastic processing, helping manufacturers produce lighter, higher-quality products.

Expancel®DU and Expancel® DE are highly suited to help produce lightweight plastic automotive interiors and are used to reduce weight and dampen sound.

Expancel® DU products are used in the production of automotive weather strips for low weight and to improve sealing.

Expancel® DU and Expancel® MB allow you to produce lighweight shoe soles and at the same time achieve a very important factor during the foaming process – control.

Thermoplastic processing methods with Expancel® Microspheres

No expensive equipment or licensing is necessary. Just add Expancel® microspheres.

Please contact our Expancel® microspheres experts.

We look forward to hearing from you.

For our existing customers, please log in to our MyNouryon customer portal.

Expancel® is a registered trademark of Nouryon in a number of territories worldwide.