CiD Technology

Nouryon's CiD technology gives PVC producers higher plant output with an improved process safety. With this technology, it is generally observed that the resin produced has a whiter color and is thermally more stable than conventional PVC. This better quality is apparently much appreciated by end-users such as window profile makers.

Recently, the technology has been tested and its advantages in improving color and thermal stability have been experimentally proven by a cooperation between PVC producer Ercros and the University of the Basque Country. The unique very fast organic peroxide initiator used in the CiD process appears to be the critical factor. Compared with other peroxides, a much lower level of this peroxide is remaining in the final PVC resin. In addition, based on thermodynamics, it was shown that its radicals are much less aggressive leading to less polymer chain defects. As there is less damage to the PVC resin and less discoloration, its whiteness and thermal stability is eventually well retained.

Your search for an improved way to produce your PVC resin ends with our CiD technology. More details are available in this publication in an ACS Journal, partially written by Nouryon’s Koen Vanduffel and André Hogt.

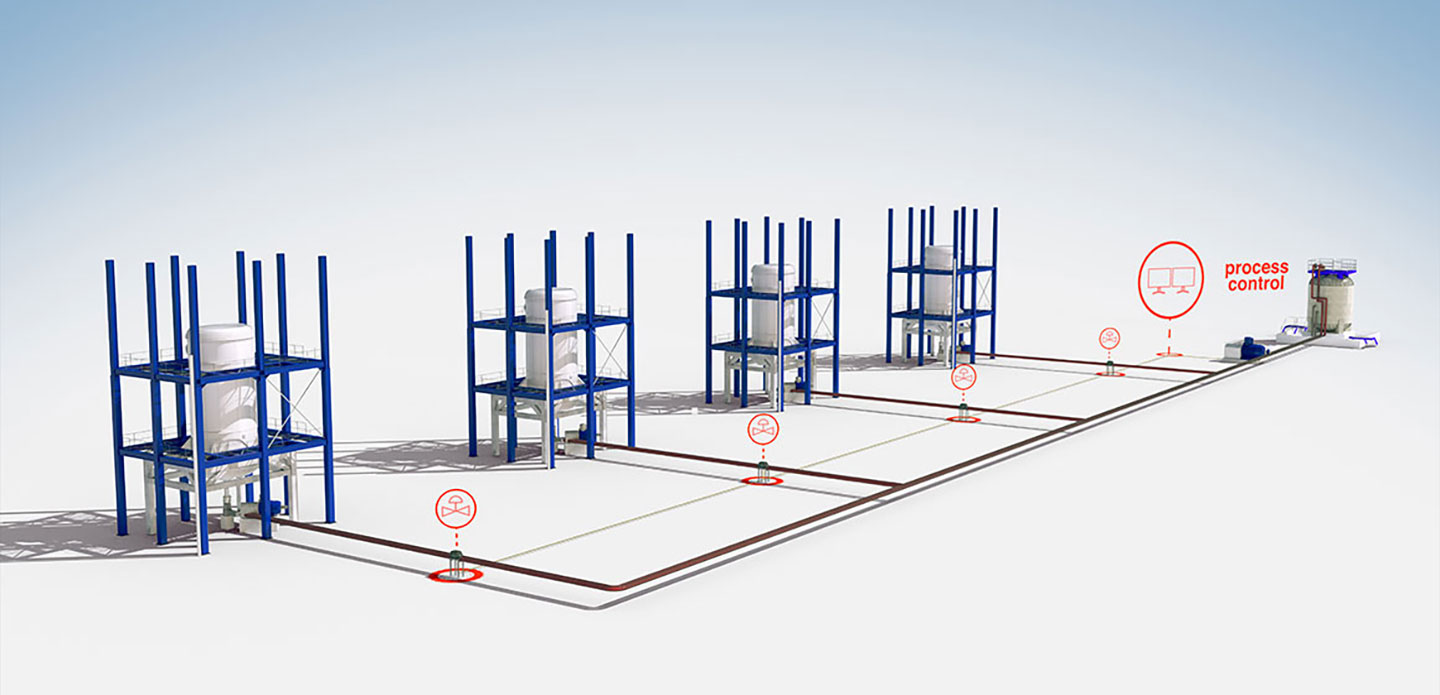

CiD tanks