Expancel® microspheres

Lightweight filler and blowing agent all in one.

Expancel® microspheres

Lightweight filler and blowing agent all in one.

Lighter, stronger, faster, cheaper, more attractive, longer-lasting, better performing, and more sustainable—today's products have a lot to live up to.

This is the world for which Expancel® microspheres were created. Since 1980, they have helped product developers and manufacturers create lighter products and reduce manufacturing costs while improving quality, adding functionality, and enabling innovation—opening a world of possibilities.

Today, you'll find them in a wide array of everyday products around the world—from the paint on your walls to the car you drive, the shoes you walk in, and the packaging that protects your food.

Lightweight filler and blowing agent all in one

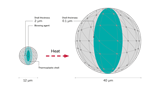

Expancel® microspheres are small spheres encapsulating a gas. When heated, the gas expands while the shell softens, resulting in a dramatic increase in volume —up to 60 times their original size. This process reduces material density without any chemical reactions, residue, or VOC emissions during expansion.

Expancel® microspheres are available in a broad range of forms—unexpanded, expanded, wet, and dry—each offered with specific thermomechanical properties and particle sizes. This versatility, along with expansion temperatures ranging from 85°C to 230°C, supports a wide range of process and application requirements, enabling integration into diverse manufacturing processes.

Expancel® microspheres offer dual functionality as a lightweight filler and a blowing agent. As a lightweight filler, they achieve exceptionally low densities—down to 25 kg/m³. Even small amounts can significantly reduce the weight of products like elastomeric cool roof coatings, paint, cultured marble, underbody coatings, sealants, and polyester putties.

Unexpanded Expancel® microspheres are excellent blowing agents for a wide range of matrices. They provide controlled foaming and stable processing, resulting in a fine, uniform cell structure. They are used as a blowing agent in applications such as shoe soles, wine stoppers, printing inks, wallpaper, and car weather strips.

From small spheres to a world of applications

Expancel® FG for food packaging offers high compressibility, no shrinkage, no moisture absorption and is approved by regulatory authorities.

Expancel® WE and Expancel® DE for elastomeric cool-roof coatings give superior reflectance and elasticity and reduce cost and weight.

Expancel® DU and Expancel® DE are used by the automotive industry to reduce weight, dampen sound and improve sealing.

The extra small Expancel® XS200 microspheres

Infusing the magic of microspheres into thin-layer interior paint

Read more

Featured applications where Expancel® Microspheres is used

Using Expancel® microspheres as a lightweight filler in paint will shorten the drying time, introduce a matting effect and provide good filling on uneven substrates.

Do you want to lower your costs and make your sealants and adhesives lighter? With Expancel® microspheres in the mix, this can happen.

In thermoplastic processing, Expancel® microspheres' uniform, closed cell structure results in a stable, controlled foaming process and is a phenomenal blowing agent on its own or combined with a chemical blowing agent.

Use of Expancel® Microspheres improves bulk or reduces grammage keeping the caliper of your board and ensuring resilient seals for food packaging, without shrinkage or water absorption.

Expancel® microspheres are extensively used as sensitizers in industrial explosives in coal, metal and quarry mining operations around the world.

Related Videos

News and events

Please contact our Expancel® microspheres experts.

We look forward to hearing from you.

For our existing customers, please log in to our MyNouryon customer portal.

Expancel® is a registered trademark of Nouryon in a number of territories worldwide.

Main body lorem ipsum